CATEGORIES

- Automatic printing machine

- Pad printing machine

- Silk screen printer

- Spray Painting Machine

- IR tunnel dryer

- Hot foil stamping machine

- UV curing machine

- Flame treatment machine

- Plate making equipment

- Consumables of pad printing

CONTACT US

- ADD: Shangsha industry Chang An Town, DongGuan City, GuangDong Province, China.

- TEL: +8613728113481

- FAX: +86-769-88734858

- E-mail: jericho@ly-printingmachinery.com sales@ly-printingmachinery.com

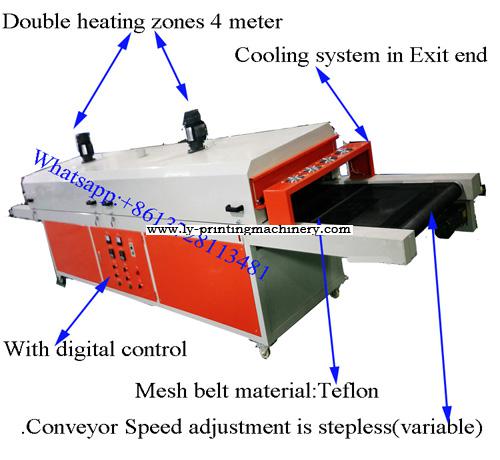

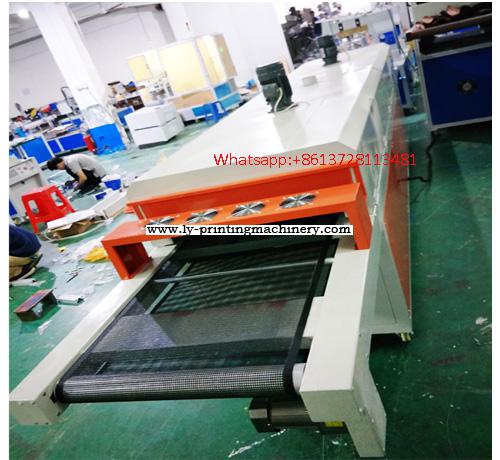

5.5M IR tunnel drying machine with cooling system

- Heating area: 4M

- With coiling system

- Stepless(variable)

- Conveyor material:Teflon

- Product description: LY-5500

PRODUCT INTRODUCTION

1.IR drying tunnel can drying all kinds of ink ( except UV ink),such as Plastisol ink, thermosetting ink,screen printing ink,pad printing ink,plastic ink,glass ink ETC.

2.It can drying variety of material ,such as fabric,plastic,matel,glass,wood,silicone Etc

3.Our IR drying tunnel could be customized, such as drying size , maximum temparature conveyor material stainless steel Teflon and other requirment, it just depend on your requirment.Ensuring good drying quality, Our IR tunnel conveyor is adopted high-temperature resistant Teflon material, Conveyor Speed adjustment is stepless(variable)

Feature

LY-5500H total length is 5.5M, Tempreture zone is 4M(Drying area),drying width is 600mm.

1.it has air circulation system via 2 fans, With exhaust ducting easy operation ,long life.

2. Famous brand motor is imported, Conveyor sprocket is adopted carbon chain standard sprocket, the main cold-drawn steel car system.

3.Microcomputer intelligent temperature control system, temperature than the general use of temperature control machine is more reliable and stable, the temperature can be segmented control.

4. Imported cotton insulation, thermal insulation effect is excellent, energy saving than the ordinary oven to save 30% electricity.

5.With sheet metal to under frame area,so that it can be dust-proof, safe, beautiful, hanging buckle structure installation, easy maintenance and combination.

6.Tunnel body is made by angle iron bar production, sub-combination of design structure, easy removal and convenient installation.

7.Oven internal lines using high-temperature sets of protection, clear and neat to facilitate maintenance.

Technical parameter

1.Conveyor length :5.5m, drying area :4m

2.Conveyor width:600mm

3.Entry end length:700mm,Exit end length:800mm

4.Machine size: (L)5500x(W)1080x(H)1500mm

5.Working power: AC 380V 50HZ

6.Temperature adjustment: 0-200 Centigrade

7.Constant temperature will be 5º C more or less

8.Temperature resolution: 1º C

9.Belt speed adustment: 0-10M/MIN

10.Gross weight: 580 KG

11.Conveyor material:Teflon

12.Conveyor Speed adjustment is stepless(variable)

13.With cooling system

14.With exhaust ducting

Jericho

Jericho